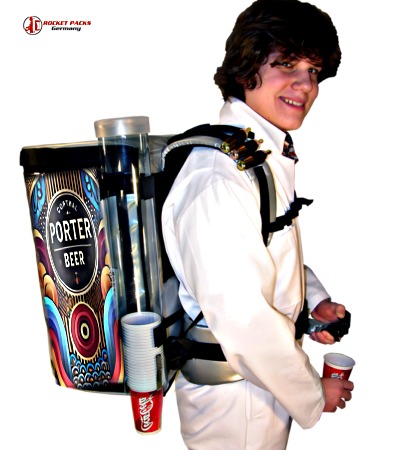

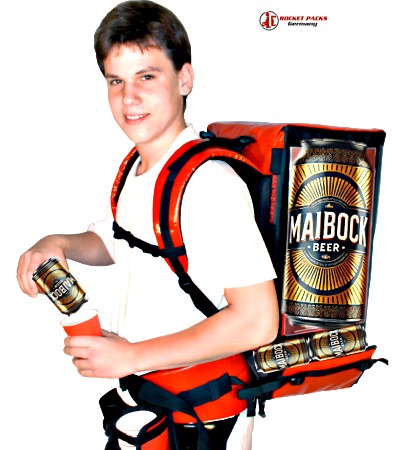

With a robust insulated tank and ergonomic harness design, the Beer Dispenser Backpack keeps drinks cold for hours and ensures comfort for long shifts. Integrated cup dispensers and an easy-to-use tap system guarantee fast service for high-traffic events. Only premium, food-grade materials are used for maximum hygiene, durability, and compliance with beverage industry standards.

Rocketpacks Beer Dispenser Backpack is ideal for mobile vendors, hospitality staff, and promotional teams. Serve beer, soft drinks, or sparkling water from the same system, and benefit from quick cleaning and hassle-free maintenance between uses. The backpack features large customizable panels, giving brands and advertisers an eye-catching space for logos and messaging at any venue.

Ergonomic design for high-performance mobile beverage service

- The Beer Backpack a mobile system developed for the distribution of beer and soft drinks.

- It combines lightness and a high-quality design.

Cost-benefit analysis: Why Rocketpacks systems lead the Asian market

- The center of gravity of the backpack is usually lower than the waist.

- As a result, I noticed that the load was concentrated on the shoulder.

- Also, some people said that the server was not attached to the body, and when it moved, the tank shook and hit the body, causing pain.

- To reduce these strains, we developed a functional rocket pack that uses our knowledge of sports equipment development and health management.

- It was introduced as a "comfort backpack".

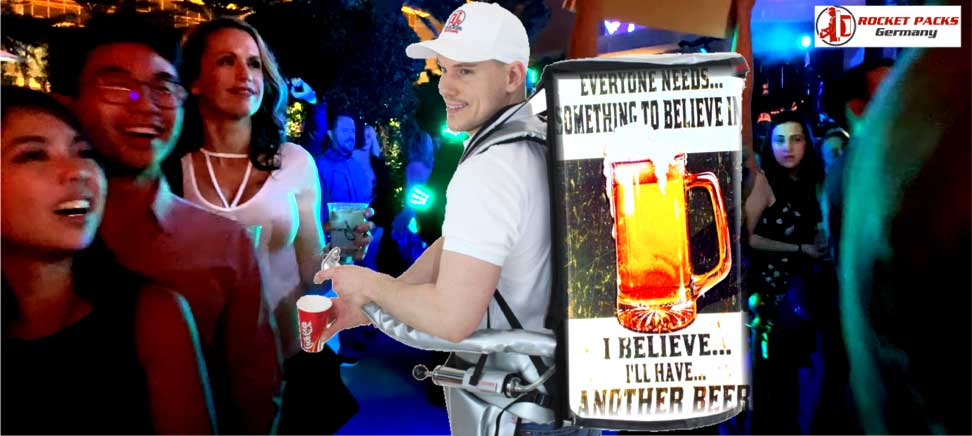

- These "Rocketpacks backpack" will be used for draught beer in every stadium and other places from the end of March when professional football opens.

Backpack for beer, rocket packs with thermal insulation for hot or cold drinks!

- (carbonated or still) Coffee, tea, hot chocolate, soup, iced tea, wine, liqueurs, shooters, juices, and more.

- Finish: Black background without advertising inlay

- Advertising supplement is provided separately Army

- Stainless steel tank, type 305, sanitary version

- Capacity: Total 11.5 liters. (Up to 60 cups)

- Weight: 15.7 kg.

- Dimensions: diameter 35 cm. Height 60 cm.

- Dimensions for advertising inserts: width 75 cm. Height 43 cm.

- Cup dispenser for dispensing cups.

- Adjustable heavy-duty belts.

- Thermal hose.

- Product Origin: Germany

Pricing models for stadiums, festivals, and major hospitality groups

- Especially since many women are responsible for providing draught beer on baseball fields, there have been many calls for a reduction of the load.

- With traditional Rocketpacks sales staff should move and sell in an excessively inclined position.

Bulk orders and international shipping rates for Hong Kong & APAC

- Features of the Rocketpacks beer backpack for the new backpack server!

- Newly developed hip belt with specifications that allow the drink backpack to be in close contact with the body

- Development of a structure consisting of a frame that follows the shape of the server bag.

- A spacer that keeps the center of gravity of the server above the waist.

- Develop a design that improves the degree of close contact with the body so that the server does not wobble on its back when moving.

Base unit costs for CO2 and gravity-fed beer backpacks

- Compared to the current product, the Rocketpacks backpack with the above three features can reduce the load on the shoulder area by up to about 20%.

- In response to the sensory evaluation, where the user is asked about the load on the shoulders, we found that the load can be reduced more than the current one.

- By applying the beer dispenser development technology for outdoor backpacks, various modifications have also been made to the shoulder strap and the hip belt to reduce the user's exposure and make them easier to use.

- Development of a new Rocketpacks backpack for a beer keg, which solves the problem of carrying and serving beverages and other such goods.

- We have developed a backpack (without draught beer container) of the new ergonomically designed draught beer backpack.