- Structure and Function of the beer keg dispenser backpack!

- The keg is a cylindrical stainless-steel drum.

- Modern kegs are often rubber-coated to protect the container from damage.

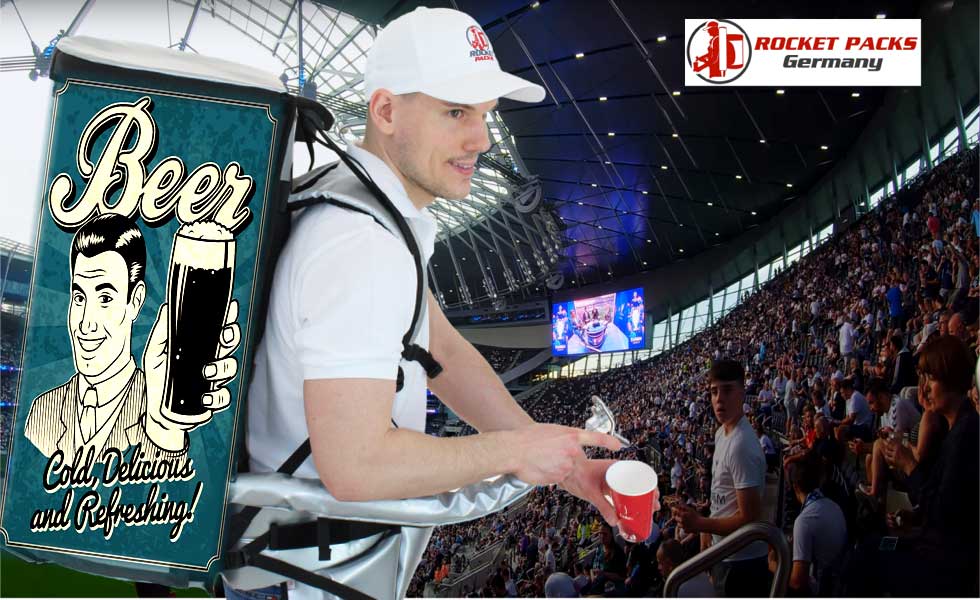

Our experience and the trust of our customers show that Rocket-packs Beer keg dispensing backpack can successfully solve the hotel management of any kind of event.

Backpack Beer Dispensing for street vending

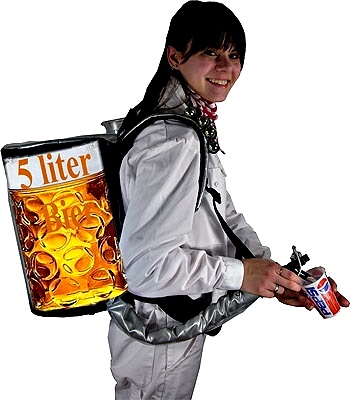

- It has two individually adjustable compartments allow access to two different products simultaneously thanks to the lateral openings.

- Its thermal insulation is perfect for keeping drinks at all temperatures.

- Also, it offers a large advertising surface.

- The propellant gas creates overpressure in the keg and the contents are pushed out through a pipe inside the keg when the tap is opened.

- The overpressure inside the keg is maintained and the foaming of the contents is reduced.

- Connection systems:

- The four connection systems mainly used by German brewers have been identified by different types (letters) to better distinguish them.

Mobile beer dispenser system developed for the distribution of beer, soft and carbonated Drinks

Fill the insulated compartments with refrigerated cans or bottles and you will be ready for sale. A large vinyl display cover allows quick change!

Why Chicago’s premier stadiums rely on Rocketpacks keg dispensing technology

- With the basket tapping head (type S), the center ram is longer than in the draft tapping head (type D) and can be recognized by the lateral V cut-outs.

- Although the two systems are mounted in the same way, they are not compatible with each other and cannot be exchanged crosswise.

- If the backpack dispensing tapping head is removed, the valve closes the keg airtight, allowing further storage of the contents and preventing the residues from drying out.

- The desired data can now be affixed to it using stickers.

- Advantage:

- You can fill the beer backpack barrels again and again with other kinds of beer.

- The proprietary Rocketpacks beer backpack connection variant is used exclusively for disposable kegs from Lightweight tanks.

- This tapping head is placed on top of the fitting and then turned at an angle of 60° for fixing.

- The keg is then tapped by pressing down on the lever.

- Some breweries mark their beer barrels with colored bands around the barrel so that you can see what is in them.

- For example, Carlsberg has marked blue-black and Bit burger green.

- But the most common way to mark a keg barrel is the so-called fitting lid.

- This lid is made of flexible or hard plastic and is pressed onto the fitting.